Industrial and chemical packaging is evolving—and spout pouches have emerged as one of the most reliable and cost-effective solutions in 2026. As manufacturers look for safer, stronger, and more efficient ways to package liquids, gels, and powders, flexible spout pouches are rapidly replacing rigid containers such as bottles, jars, cans, and drums.

In this guide, we break down why spout pouches have become the new standard for industrial and chemical products, along with the materials, performance tests, and applications that matter most.

1. Why Industrial Brands Are Switching to Spout Pouches

Industrial and chemical companies face strict packaging requirements: safety, durability, leak prevention, and transportation stability. Spout pouches address all these needs while offering major cost and sustainability advantages.

Key reasons brands choose spout pouches:

- Lower packaging and transportation costs

- Reduced risk of leakage during shipping

- Better chemical resistance

- Space-saving for storage and logistics

- Strong barrier protection

- Customizable pour spouts for controlled dispensing

Companies that export chemical products find spout pouches especially beneficial due to their lightweight design and reduced freight cost.

2. High-Barrier Materials for Chemical Safety

Industrial-grade spout pouches must withstand harsh chemicals, oils, solvents, detergents, and corrosive substances. To ensure safety, these pouches are made with advanced multilayer structures such as:

Common material structures:

- PET/NY/PE – High mechanical strength + good barrier

- PET/AL/NY/PE – Maximum oxygen & moisture barrier

- PET/NY/CPP – High heat resistance

- Mono-material PE – Recyclable option for certain chemicals

- NY/PE – Strong puncture resistance

These layers provide protection against:

- Corrosion

- Odor migration

- Moisture penetration

- Chemical reactions

- UV exposure

- Puncture and abrasion

This makes spout pouches reliable even for aggressive products like automotive fluids or strong detergents.

3. Performance Tests for Industrial Spout Pouches

Industrial & chemical products require strict quality control. High-quality suppliers (like Asia Packaging Group) run multiple tests to ensure absolute safety.

Essential tests include:

✔ Drop Test (Up to 10 Meters)

Ensures the pouch won’t burst during transport or rough handling.

✔ Pressure Resistance (Up to 200 kg)

Proves the pouch can withstand stacking and warehouse pressure.

✔ Burst Strength Test

Tests internal pressure resistance, especially for liquids and gels.

✔ Chemical Compatibility Test

Ensures the materials don’t react with:

- oils

- acids

- detergents

- industrial solvents

✔ Seal Strength Test

Guarantees strong seams and no leakage, even under stress.

These tests ensure the pouch is safe for global shipment and industrial environments.

4. Common Industrial & Chemical Products Using Spout Pouches

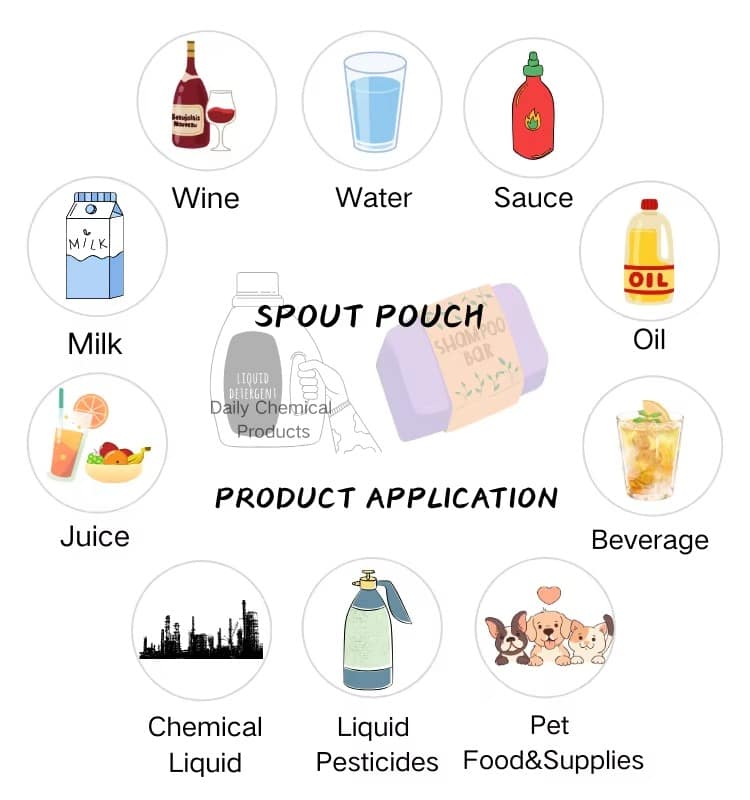

Spout pouches are extremely versatile for both liquid and semi-liquid industrial products.

Typical applications include:

- Motor oils & lubricants

- Coolants, antifreeze & automotive fluids

- Detergents & cleaning chemicals

- Fertilizers & agricultural liquids

- Paints, coatings & colorants

- Adhesives & industrial glue

- Solvents & alcohol-based liquids

- Construction chemicals (waterproofing agents, grout additives)

- Hand sanitizer & disinfectants

- Ink, dyes & pigments

The pouch’s durability and controlled dispensing spout make it ideal for safe industrial use.